Maintenance Tips for Heavy Duty Trailer owners.

Heavy duty trailers work hard. From long highway runs to rough rural roads and worksites, they're exposed to dust, moisture, heat and heavy loads everyday.

Without regular maintenance, even the toughest trailer can wear prematurely, become unsafe, or fail when you need it most.

In this guide, we'll walk through essential heavy duty maintenance practises that we put in our manuals to help our customers, and all trailer owners, improve safety, reduce downtime, and extend the lifespan of your trailer, especially in Australian conditions.

TYRE CHECKS

Tyres are one of the most critical, and overlooked, components of any trailer.

What to Check

- Tyre Pressure (before every trip)

- Uneven or excessive wear

- Sidewall cracks or bulges

- Correct load rating for the trailers ATM

Tyre Pressure

Ox Trailers standard tyre offering - 245/75/R16 All Terrain Tyre

Single - 1400kg at 35-45 PSI*

Dual - 1260kg at 35-45 PSI*

*Please refer to the tyre manufacturer for the correct pressure and load rating for any tyres other than those listed above.

Why it Matters

Under-inflated or overloaded tyres can overheat, wear unevenly, and increase the risk of blowouts - especially on long hauls or hot bitumen roads.

Pro Tip

Always match tyre pressure to the loaded weight, not the empty trailer.

Ox Advantage

Ox Trailers are fitted with correctly rated tyres designed to suit the trailers load capacity and intended use.

WHEEL BEARINGS & LUBRICATION

Wheel bearings carry enormous loads and require regular attention.

Maintenance Tips

- Inspect bearings every 6-12 months (more often for off-road or heavy use)

- Repack with high-quality grease

- Check for heat after towing - warm is normal, hot is not.

Why it Matters

Dry or damaged bearings can seize without warning, leading to costly roadside breakdowns or wheel loss.

Ox Advantage

Quality Dual Row Taper Roller Bearings on Dual Axle Trailers. These are 3000kg each, with a triple lip marine seal with a secondary O-Ring seal incorporated into the dust cap. They come with a 3-year manufacturer's warranty.

BRAKE INSPECTIONS

Brakes are for both legal compliance and road safety

What to Inspect

- Brake pads/shoes for wear

- Electric brake wiring and connections

- Breakaway system battery and function (for trailers over 2000kg ATM)

- Override brake fluid (if applicable)

How Often

Visual checks before trips

Full inspections at least every 6 months

Why it Matters

Faulty brakes increase stopping distances and may result in fines, failed inspections or accidents.

Ox Advantage

Ox heavy-duty trailers are fitted with ADR-Compliant, 12-inch Electric Drum Brakes, and a Ratchet Trailer Handbrake as standard.

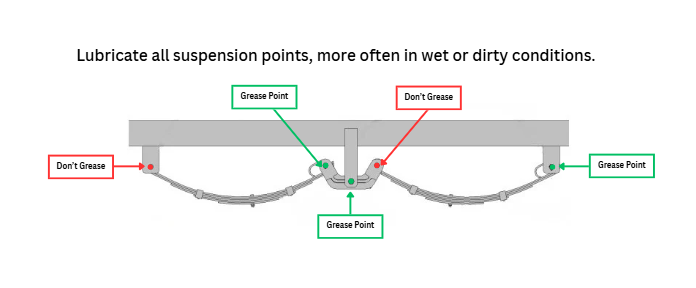

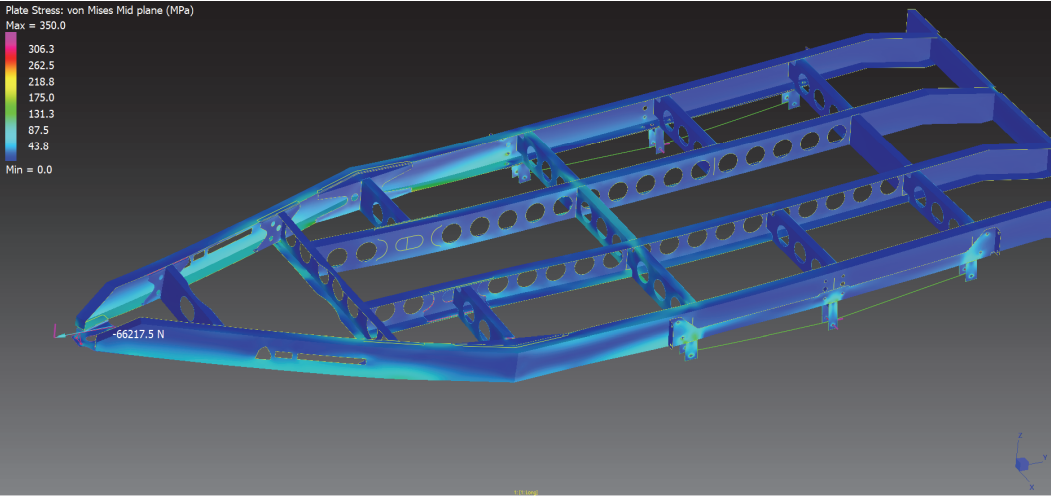

SUSPENSION & CHASSIS CHECKS

Your trailers suspension and frame absorb constant stress.

Key Areas to Inspect

- Leaf springs or rocker roller assemblies

- Shackle bolts & bushings

- Grease Points

Why it Matters

Word suspension leads to poor handling, uneven tyre wear, and structural damage over time.

Ox Advantage

Ox Trailers are engineered with a Load Sharing Leaf Spring Suspension Set to ensure as safe and stable trailer on and off the road.

Nature's Symphony

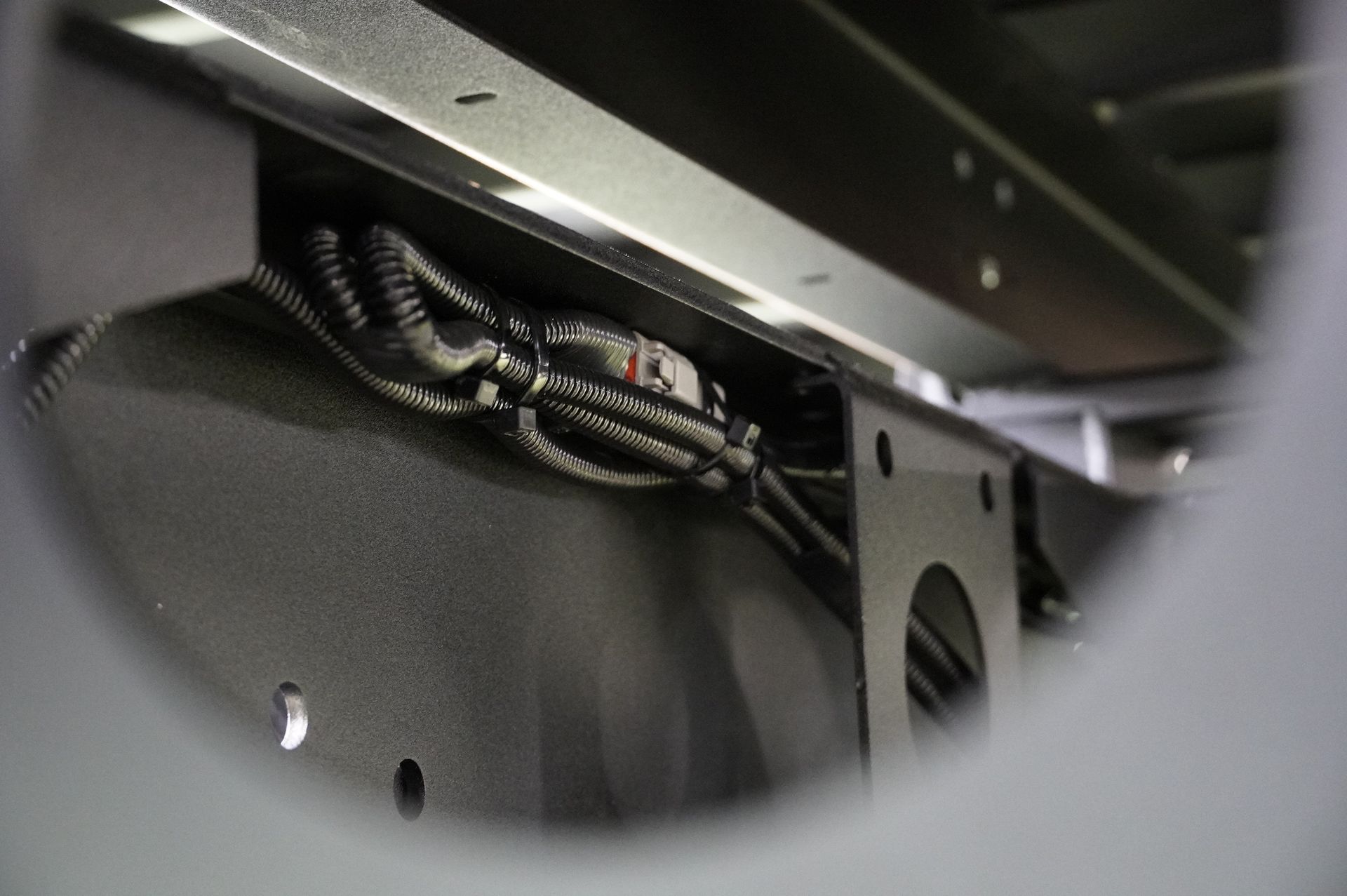

ButtonLights, Wiring & Electrical Systems

Trailer lighting is a legal requirement, and essential for safety.

Maintenance Checklist

- Test brake lights, indicators, and clearance lights

- Check for loose plugs or damaged wiring

- Clean connectors regularly to prevent corrosion

Why it Matters

Electrical faults are one of the most common reasons trailers are defected or involved in accidents

Ox Advantage

All wiring on Ox Trailers is fed through a protective corrugated conduit and secured to a wire lacing bar running the length of the chassis, it is secure, safe and easy to access if needed.

RUST PREVENTION & GENERAL CLEANING

Dust, mud, salt air, and moisture can all shorten a trailer's lifespan.

Best Practises

- Wash down after coastal or muddy use

- Store undercover where possible

Why it Matters

Rust weakens structural components and reduces resale value.

Ox Advantage

Every component of the Ox Trailer Chassis, Deck and Accessories are fully sandblasted to white steel, they are then coated with a zinc-rich primer before finished with a durable Dulux top coat.

A heavy duty trailer is an investment. With regular maintenance, you'll not only extend it's working life and protect it's value, but you'll be protecting the safety of yourself, your team and others on the road. Not to mention the gear actually on the trailer!

Choosing a high quality Australian-made trailer makes maintenance easier from day one.

Explore the range today.

Have an Ox and want to know just how to keep it as fresh as the day you picked it up? See below for our Operators Manuals.