Trailer load capacity, methods of manufacture, and drawbar configurations are some of the most important buying decisions to consider when looking at buying a trailer.

With the road conditions deteriorating rapidly, costs of living/running a business increasing rapidly, and consumers demanding better value for their money; quality Australian built, and well designed trailers are becoming more and more of a “must have” in everyday trades people’s lives.

Read on to find out more about what considerations you must take when buying a trailer.

LOAD CAPACITY:

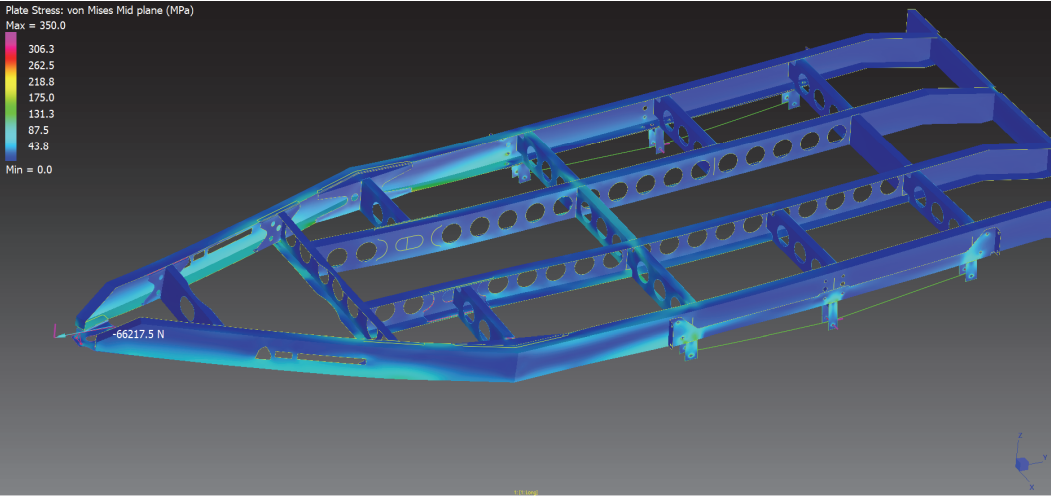

All our trailers have been meticulously designed and engineered to withstand the load requirements and daily rigors all trailers are subjected to. Regardless of the ATM/GTM or who the end user might be we have never skimped out or taken short cuts in the strength of our trailers. Our trailers are one of the heaviest on the market and in our eyes, strength far outweighs the extra 100-200 kgs of extra payload claimed by most competitors and this is just one of the many reasons that we are a favorite. We use crossmembers every 300mm to reduce the chance of floor sheets bowing/bending, we also have increased the floor plate thickness typically used in the industry to 3.0mm unlike many competitors who use 1.6mm or 2.0mm floor sheets which do not stand up over time to the load requirements.

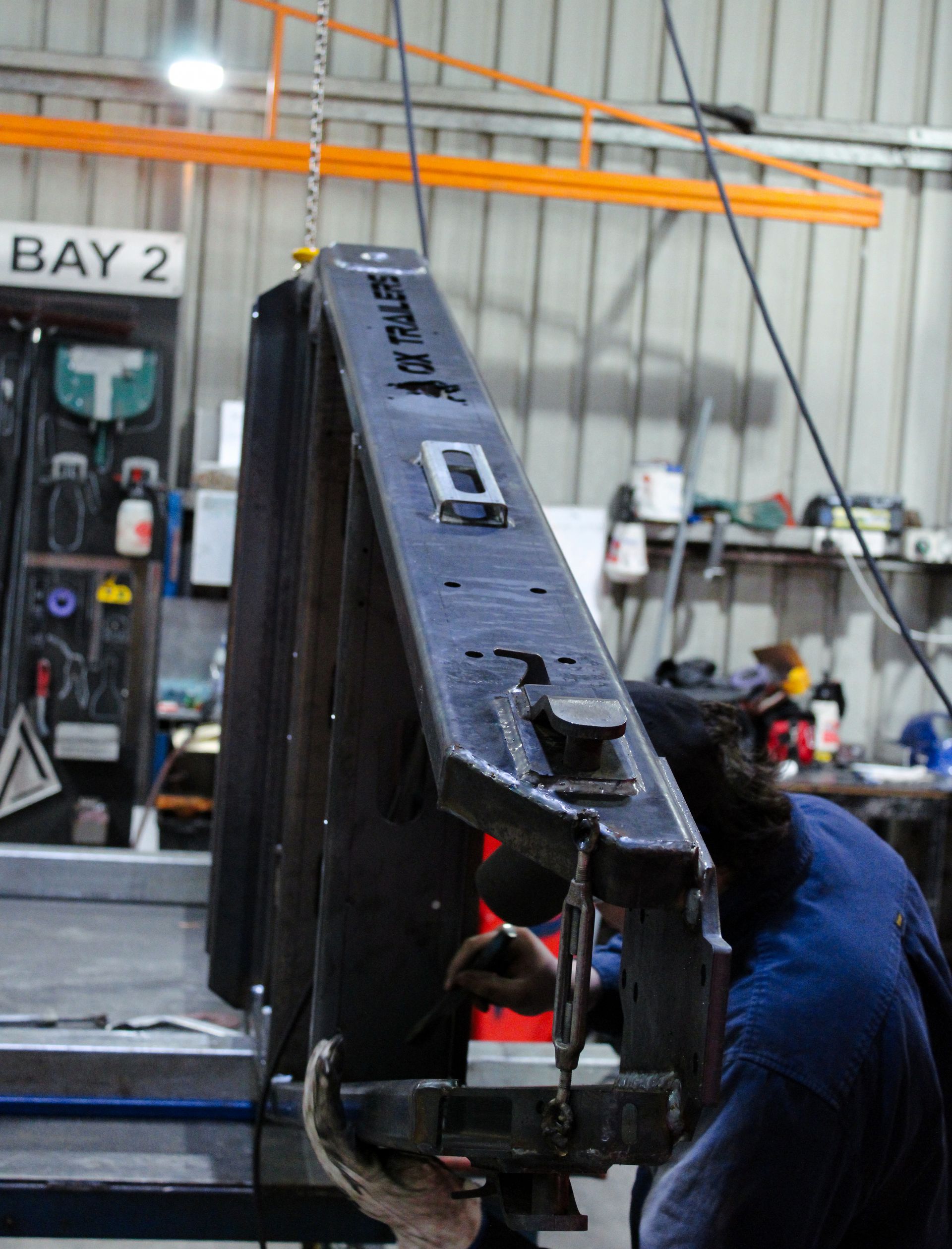

MANUFACTURING METHODS:

The method in which a trailer is manufactured plays an important role in the overall durability and lifespan of a trailer.

Welding is not always best, neither is the use of bolts. If the trailer chassis is simply fully welded together, the joints won’t flex and can cause cracking and metal fatigue, hence why our chassis is a combination of both. Look for Fisch Plates (usually welded & located on joins) and gusset plates along drawbars for peace of mind.

In some areas, bolts are ideal for added accessories when options are removable. When choosing a trailer with bolt on accessories, look for items such as nyloc nuts, spring washers, split pins and loc-tite bonding gel which help prevent the possibility of bolts from vibrating loose.

TRAILER DRAWBAR CONFIGURATION:

The basic configuration of the trailer’s drawbar is a key factor when it comes to the strength, durability, and usability of the trailer. Below are a few things to consider:

Length of the Drawbar.

- A short trailer drawbar indicates not only weakness; it also affects the drivability and stability of the trailer when backing up or turning.

- A longer drawbar significantly adds to the overall strength and longevity and allows for a more reasonable turning radius and added clearance to the vehicle whilst backing up.

- A longer drawbar is also best for extending the distance from the tow vehicle rear axle to the front axle of the trailer, this allows for more stability and durability on the road.

Axle Location

- The axle location is key for ensuring maximum load stability. Our axle set is placed deliberately rear of the center of the trailer for stable and safe load transportation unloaded or loaded.

There are many indications to look for that show whether a trailer is well built or not, with the main three being the load capacity, manufacturing techniques used and the trailer drawbar configuration. With most trailers it can be obvious that it is cheaply built or poorly designed, but it is always a good idea to check over the main indications to ensure it will meet your hauling needs safely.