Sure, you can build your own trailer, but registering it for on-road use is very difficult.

From strict engineering processes to destructive testing standards, VTA's (Vehicle type approvals) and more, obtaining a VIN (Vehicle Identification Number) for these trailers can be time-consuming and costly.

From 1st July 2023, all trailers need to meet full compliance to relevant the Australian Design Rules (ADRs).

Vehicle Standards Bulletin 1 (VSB1) will no longer be accepted as an alternate method of compliance for new trailers.

TMR (Transport Main Roads) specifies these rules and regulations in their Bulletin: Trailers Aggregate Trailer Mass 4.5 Tonnes or Less.

Read below for our summary of this document for an easy reference to the regulations involved in building your own Pig trailer.

TRAILER REGISTRATION

No Part of the registration plate may be more than 1300mm from the ground.

No part of the trailer can obscure any part of the registration plate

Registration plate lights must be fitted.

The lamp must illuminate the registration plate with whitelight

No light from the lamp may be directed rearwards.

TRAILER MAXIMUM DIMENSIONS

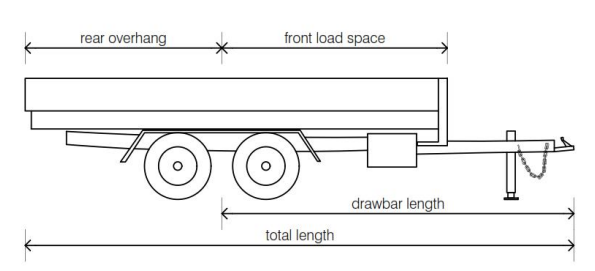

LENGTH

Pig Trailers

- Maximum drawbar length: 8500mm

- Maximum rear overhang: 3700mm or length of the front load space, whichever is smaller

- Maximum length: 12,200mm

WIDTH

- Maximum width: 2500mm, Overall width includes mudguards, side mounted spare wheels, side mounted racks, and awnings, but does not include lamps required for compliance, permanently affixed load restraint devices, or tyre pressure and inflation devices.

HEIGHT

- Maximum height: 4300mm

- Maximum height for livestock trailers: 4600mm

Additionally, the document specifies that all trailers must have a running clearance of 100mm or greater.

TRAILER LIGHTING REQUIREMENTS

GENERAL REQUIREMENTS:

- Trailers must have compliant lamps and reflectors that are appropriate for their specific location and use.

- Lamps and reflectors must be fitted according to the provided instructions.

- No part of the trailer or its equipment should obstruct the lamp output or obscure the reflectors.

- Lamps on a trailer must operate in conjunction with the corresponding lamps on the towing vehicle.

- Pairs of lamps or reflectors must be spaced equality on either side of the centerline of the trailer

ESSENTIAL LIGHTING:

All trailers must be fitted with:

- Rear Position lamps

- Rear brake lamps

- Rear indicator lamps

- Rear reflectors

- Rear registration plate lamp

- Front reflectors

- Side reflectors

Trailers longer than 4000mm and wider than 1600mm, or 1800mm, must also have front position lamps.

Trailers wider than 2100mm must have:

- Front and rear clearance lamps

- Side-marker lamps

Trailers longer than 6000mm must have side-marker lamps.

Trailers must be fitted with two rear tail lamps, brake lamps, indicator lamps, and reflectors.

The specific requirements for these include:

- Tail lamps: Red, 350mm minimum height, 1500mm maximum height, no more than 400mm from the trailer edge, minimum of 600mm apart.

- Brake lamps: Red

- Indicator lamps: Amber

- Reflectors: Red, 250mm minimum height, 900mm maximum height, no more than 400mm from the trailer edge, minimum of 600mm apart.

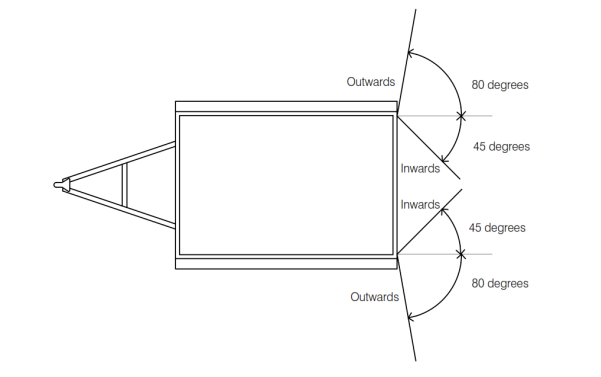

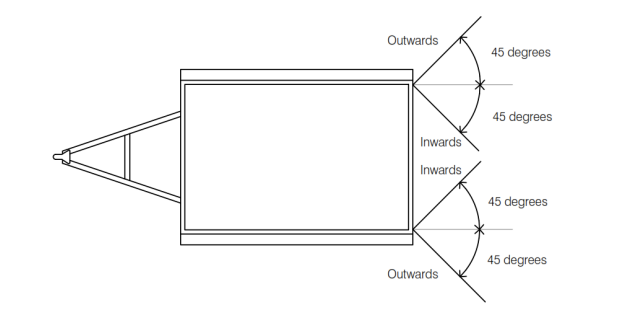

The lamps and reflectors must have specified geometric visibility angles to ensure they are seen from various perspectives.

TRAILER WIRING INSTALLATION

SUPPORT AND PROTECTION:

- Wiring must be supported at intervals not exceeding 600mm along it's length.

- Insulated at joints

- Located to prevent overheating or contact with moving parts

- Protect from chafing

- Edges of holes in metal through which wiring passes must be rolled or brushed with a rubber grommet or similar.

GROUND (EARTH) RETURN:

- An earth (ground) return wire must be provided between the trailer and it's tow vehicle.

PLUGS:

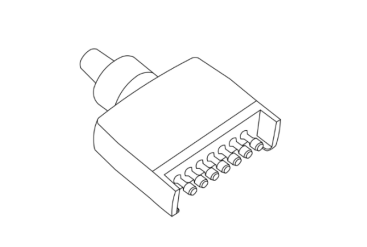

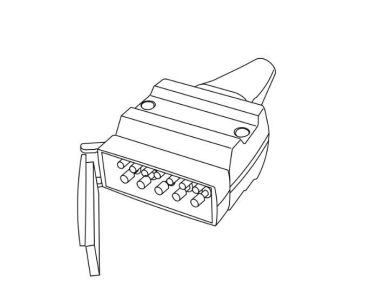

- Trailers up to 3500kg ATM must use 7 or 12-pin plugs that comply with Australian Standard AS 4177.5-2004

Pin Wiring Configuration:

7-pin plug:

- Pin 1: Left-hand indicator (Yellow)

- Pin 2: Reversing signal (Black)

- Pin 3: Earth (ground) return (White)

- Pin 4: Right-hand indicator (Green)

- Pin 5: Service brakes (Blue)

- Pin 6: Tail (stop) lamps (Red)

- Pin 7: Tail lamps, clearance lamps, and side-marker lamps (brown)

12-pin plug: Additional pins include battery supply, auxiliaries, and rear fog lamp circuits.

OTHER ELECTRICAL SYSTEMS:

- Electrical installation intended for connection to an AC power system other than the tow vehicle must comply with Australian Standard AS/NZS 3001:2008

TRAILER BRAKE REQUIREMENTS

750KGS GTM AND UNDER

- Brakes are not required on trailers with a Gross Trailer Mass (GTM) of up to 750kg

OVER 750KG GTM:

- Trailers exceeding 750kg GTM must be equipped with an efficient service braking system.

OVER-RUN BRAKES:

- These may be used on trailers with a GTM up to 2000kg

AXLES REQUIREMENTS:

- Up to 2000kg GTM, brakes may be fitted to only one axle

- Over 2000kg GTM, brakes must operate on all wheels.

Emergency Braking System (Breakaway Brakes):

- Trailers over 2000kg GTM must be fitted with an efficient emergency braking system.

- This system must cause the immediate application for the brakes should the trailer become disconnected from the tow vehicle.

- The brakes must remain applied for at least 15 minutes under these circumstances.

EFFICIENCY OF BRAKE SYSTEM:

An efficient brake system may be demonstrated by:

- Test results to UN Regulation 13.

- Test results using the performance requirements applicable to trailers over 4.5 tonnes as identified in sections 8, 11, 12, 13,14 and 23 or ADR 38/05.

- Test results to the requirements determined by the manufacturer, which may be based on other international low ATM trailer braking regulations and/or on-road low ATM trailer braking regulations in Australia.

TRAILER DRAWBARS, SAFETY CHAINS, + COUPLINGS

DRAWBARS

Strength Requirements:

- Must withstand forces of longitudinal tension and compression, transverse thrust, and vertical tension and compression without residual deformation, breaks, cracks, or separation of components.

- Longitudinal tension and compression force: 1.5 x 9.81 x ATM (kg)

Fatigue Resistance:

- Strength and fatigue resistance may be demonstrated through approved calculation procedures

SAFETY CHAINS

General Requirements:

- Must be fitted to all trailers without an emergency brake system (breakaway brakes) and all trailers with rigid drawbars.

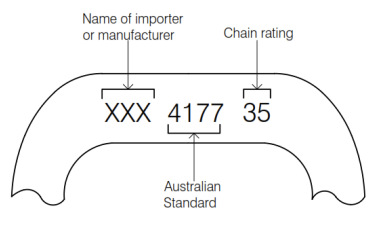

- Chains must comply with Australian Standard AS 4177.4-2004 for trailers up to 3500kg.

Trailers up to 2500kg ATM:

- Require at least one safety chain

- Chains must comply with AS 4177.4-2004

Trailers over 2500kg but not exceeding 3500kg ATM:

- Require two safety chains, compliant with AS 4177.4-2004 or safety cable with equivalent certified load rating.

Trailers over 3500kg ATM:

- Require two safety chains, made from steel of a minimum 800 MPa breaking stress, compliant with AS 2321-2001.

- Minimum breaking load of each chain must be greater than the trailer ATM with a minimum chain size of 6mm.

Attachment Points:

- Must be attached to a substantial structural member of the trailer and located near the trailer coupling.

- Must withstand longitudinal and vertical tension forces without residual deformation or component separation.

Markings:

- Chains must be marked with the manufacturer's identification, "4177", a hyphen, and two digits indicating the rating, repeated on every fourth link.

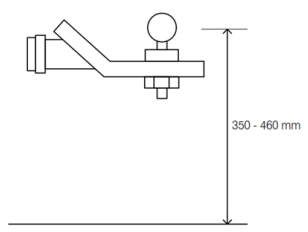

COUPLINGS

General Requirements:

- Must be quick release couplings with a positive locking mechanism and a separate means or automatically retaining the locked position, verifiable by visual examination.

- Applicable for trailers with an ATM up to 3.5 tonnes, and those between 3.5 tonnes and 4.5 tonnes.

50mm Ball Couplings:

- Must comply with Australian Standard AS4177.3-2004 for ball couplings.

- Must be marked with the manufacturer, trademark, "50" for the ball diameter, and the rating (750kg, 200kg, or 3500kg)

MUDGUARDS

FUNCTION

All trailer wheels must be fitted with wheel guards (mudguards) to:

- Prevent other road users against thrown up stones, mud, ice, snow and water.

- Help prevent people from contacting the moving wheels.

DESIGN

Mudguards can be formed by any of the following:

- The trailer's body structure.

- Specifically shaped covers over the wheels

- Mud-flaps

For trailers with two or more axles forming an axle group on each side:

- Separate mudguards may be fitted to each wheel.

- A single continuous mudguard covering all wheels may be fitted.

WIDTH

Mudguards must be wide enough to fully cover:

- The full width of the widest tyre and wheel combination that may be fitted by the manufacturer as options.

Note: For a dog trailer with steerable front wheels, the width requirement applies only with the wheels in the straight-ahead position.

LENGTH

Trailers with a GTM (Gross Trailer Mass) not over 3500 kg can comply with either of the two approaches below:

Approach 1:

- The mudguard must extend at least as far forward as a position indicated by a vertical line placed at the leading edge of the tyre.

- The mudguard must extend at least as far rearwards and downwards as a position indicated by a horizontal line placed 230mm above the road.

- Note: The 230mm rear clearance dimension can include the use of a mud flap. For off-road vehicles, this clearance can be increased to 300mm. This requirement does not apply if the mudguard extends to a point within an area formed by the ground and a line drawn at 20 degrees upwards from the contact point of the tyre with the ground.

These requirements are designed to ensure that mudguards effectively protect road users and prevent contact with moving wheels.

TRAILER WHEELS AND TYRES

REQUIREMENTS

All tyres fitted to the trailer must be of suitable specifications for the trailer's intended use. These specifications include size, speed rating, and load rating.

All wheels and tyres (including retreaded tyres) must comply with the appropriate Australian Design Rules (ADRs). These include:

- ADR 23/03 Passenger Car Tyres

- ADR 95/... Installation of Tyres

- ADR 96/... Commercial Vehicle Tyres

- ADR 42/... General Safety Requirements

TYRE PLACARD

- Trailers with a GTM not exceeding 3500kg must be fitted with a tyre placard.

- The placard must include at least the manufacturers recommended tyre size, tyre load rating, speed rating, and cold inflation pressure.

- The placard should be made of durable material and positioned where it can be easily seen.

WHEELS

- All wheels fitted to the trailer must be suitable with respect to their dimensions, speed, and load performance characteristics.

GENERAL TRAILER REQUIREMENTS

VEHICLE PLATE

- All trailers must have a durable vehicle plate, permanently attached by welding or riveting.

- The information must be embossed, indentend, etched or engraved in English, using block letters and numerals not less than 2.5mm high.

- The plate must include the manufacturer's name, or vehicle make, vehicle identification number (VIN), aggregate trailer mas (ATM), gross trailer mass (GTM), and tare mass.

VEHICLE IDENTIFICATION NUMBER (VIN)

- All trailers must have a unique 17-character VIN that meets the requirements of ADR 61/03

- Some states require the VUN to be stamped onto a substantial part of the trailer (e.g. drawbar) for registration purposes. A secondary VIN is recommended in addition to the one on the vehicle plate.

CARRYING PASSENGERS

- Trailers must not be designed or used for carrying passengers.

PROJECTIONS

- All exterior fittings must be designed and attached to reduce the risk of injust. Exterior surfaces should not have pointed or sharp edges.

SEMI-TRAILER REAR UNDER-RUN IMPACT PROTECTION:

- Semi-trailers over 3500kg GTM must be equipped with rear under-run impact protection, consisting of a bumper meeting specific height and position requirements.

These requirements ensure the safety, structural integrity, and usability of trailers and caravans according to Australian standards.

TRAILER TESTING REQUIREMENTS + PROCEDURES

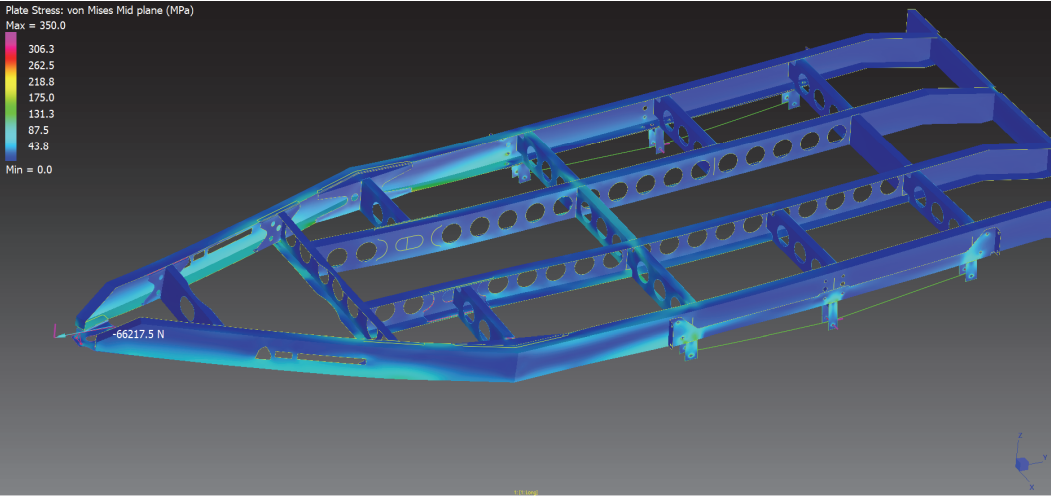

DRAWBAR STRENGTH + SAFETY CHAIN ATTACHMENT POINT STRENGTH:

TEST EQUIPMENT:

- A test rig that can accept the trailer or the relevant portion to which the drawbar is attached.

- Fixtures to restrain the trailer on the test rig during testing

- A loading device, such as a hydraulic cylinder, to apply test loads.

- Fixture to attach the loading device to the drawbar, typically a towing coupling of appropriate size.

- Force measurement devices like a pressure gauge or a load cell.

- Amplifiers and readout instruments to record test load versus time.

- Time measurement tools like a stopwatch.

TEST PROCEDURE:

Securely attach the trailer in its road-wise position to the test rig.

Apply test loads to the drawbar coupling as follows:

- Longitudinal tension and compression = 1.5 x aggregate trailer mass x 9.81.

- Transverse thrust = 0.5 x aggregate trailer mass x 9.81.

- For rigid drawbars, vertical tension and compression = 0.5 x aggregate trailer mass x 9.81.

Apply the following loads to each safety chain attachment point:

- Longitudinal tension load in Newtons = aggregate trailer mass x 9.81

- Vertical loads in Newtons = 0.5 x aggregate trailer mass x 9.81

ANALYSIS OF RESULTS:

Examine the drawbar and it's attachments to the trailer, and the safety chain attachments for any loss of attachment, distortion, or failure affecting the safe drawing of the trailer.

Reporting of Results:

Prepare a report describing the trailer and drawbar, the safety chain attachments tested, the loads imposed, and the results of the examination.

In conclusion, if you do choose to build your own trailer, we wish you the very best. Afterall, it's how we started!

Just be sure to read the full version of the document here.

If the above information looks too complicated for you and if you're thinking that building your own trailer might just be too big of a task...

Simply Get a Quote to let us do the hard work for you.