The Flood of Imports. Why the Choice Matters

The Australian market is filled with imported options, often advertised as budget-friendly solutions. But when it comes to safety, compliance and long-term performance, the difference between an imported trailer and one built here in Australia is significant.

QUALITY STANDARDS YOU CAN TRUST

Australian-made trailers are built to meet Australian Design Rules (ADR) and engineering standards. This ensures that every component of the trailer, from the position of the lights and the welds, the wiring, the axles and the braking system is designed for compliance, safety and reliability. Something that cannot always be guaranteed with low-cost overseas imports.

BUILT FOR AUSTRALIAN CONDITIONS

From blistering heat and red dust roads to endless highways and off-grid job sites, Australian conditions demand more from a trailer. Local manufacturers live and work within these conditions; their trailers are tested and engineered exactly for these challenges, meaning you get a trailer designed to thrive where you'll actually use it. Built in the country, for the country.

SUPPORTING LOCAL INDUSTRY

Every purchase of an Australian-made trailer keeps money in the local economy, supports skilled trades, and helps ensure jobs remain in manufacturing. Buying local isn't just about the product. It's about backing the people who keep Australia moving and growing.

LONG-TERM VALUE VS. CHEAP IMPORTS

While imported trailers may seem attractive upfront, the reality is often costly. Frequent repairs, shorter life spans, and poor resale value can outweigh the initial savings. By contrast, Australian-made trailers hold their value, deliver safer performance and require less long-term maintenance.

CASE STUDY: IMPORTED VS. AUSTRALIAN TRAILER

Our customer, TDK Electrical, had an imported trailer that broke under the pressure of his constant use. His trailer was built using traditional RHS Box section steel, overtime, it proved vulnerable to wear and tear, eventually weakening to the point where it cracked.

The result? His team ended up stranded on the side of the road. Thankfully, noone was hurt, but those who have been through the same experience know just how dangerous it can be.

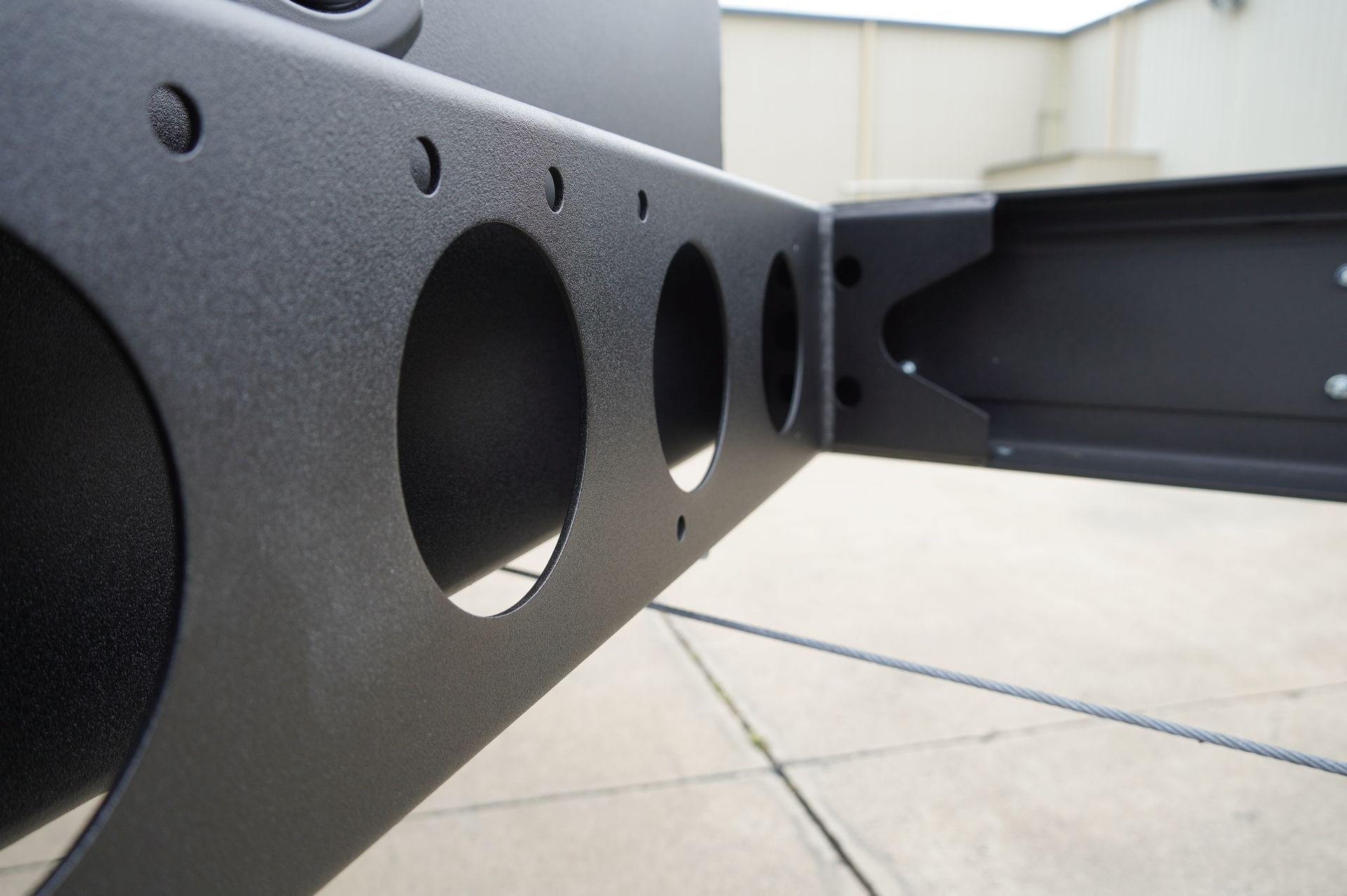

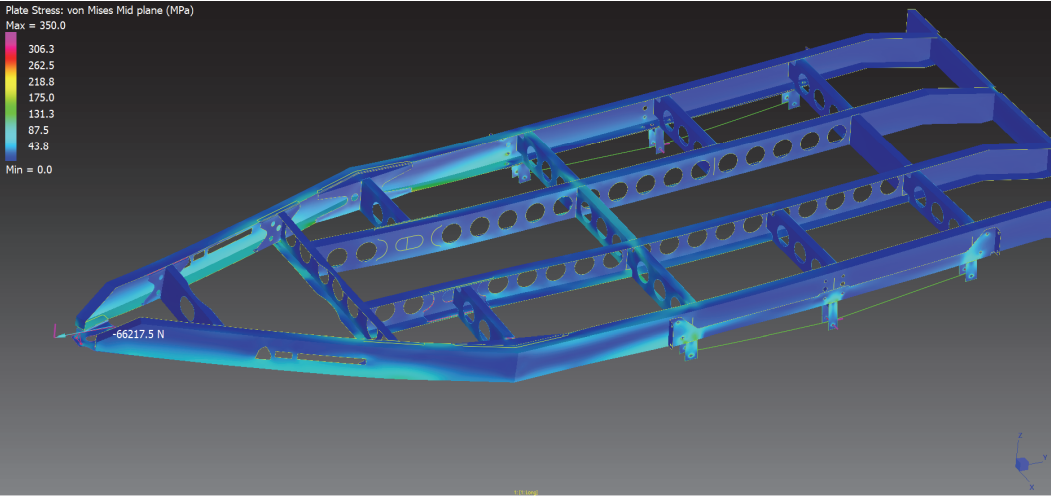

By comparison, his new trailer is an Ox, was built by Australians, for Australian conditions. The chassis of an Ox Trailer is 180mm x 65mm x 5mm 350 Grade Steel C-Section Channel that runs the full length of the trailer.

- 180mm x 65mm x 5mm is a massive upgrade in size from the traditional 75mm x 50mm x 3mm or 150mm x 50mm x 5mm box section used in most trailers.

- Not only is 350 Grade steel more resistant to wear and corrosion, but the C-Section design also allows for more flexibility, full weld access and full wiring and bolt access.

- The open chassis design also means the chassis can be thoroughly sandblasted, primed and powder coated, inside and out, for superior long-term durability.

This trailer, like all Ox Trailers, is built right from the ground up. TDK Electrical now has a trailer that's built stronger and safer for him and his team. And just look how good it looks behind his cruiser!